| RPT |

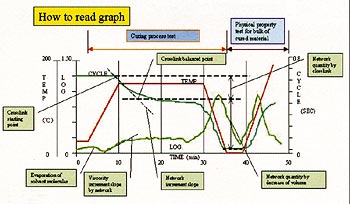

All materials become a solid state from a liquid state through some action (heat, light, time and others), and produce various physical properties. The change of phase from liquid to solid causes various problems. Due to this fact, there are cases that the expected performance design cannot be achieved and the performance of the material is lowered and changed by some environmental factor in the process. The most important evaluation item among the material evaluations is to pursue the aging change of the chemical-physical performances in the process of curing and drying from a liquid state to a solid state.

The instrument developed for this evaluation purpose is a rigid-body pendulum type physical properties testing machine, model RPT-3000W. |

|

| Sample of how to read a graph |

|

Features

- Use a wide variety of test substrates

- Use a wide range of temperatures: -100 °C to 400 °C

- Schedule testing under varying temperatures: up to a10 step

difference (plus or minus)

↓

Benefits

- Simulation can identify the most effective production schedule and the best materials composition for the designed property.

|

| Click to enlarge |

|

|

|

| Available to Evaluate Materials in Versatile Fields |

| With this instrument, one can evaluate the curing and drying process of organic high polymeric materials, and their bulk physical properties, or evaluate the surface's physical properties and other materials, such as inorganic material like concrete, cosmetics, paper and foods in the operational temperature range from -100 degrees Celsius to 400 degrees Celsius. |

|

| -MEASUREMENT- |

Fix the test piece coating plate on the cooling/heating block. Set the pendulum so that the knife-edge, the fulcrum of the swing,

comes vertically into contact on the test piece coated surface. Apply free vibration to the pendulum. For measurement of physical properties, use a cylindrical edge. By analyzing this vibration, the curing process and surface's physical properties can be evaluated. |

| Rigid-body pendulums |

Coating tool(CT) |

Cooling/heating block(CHB-100) |

Cooling/heating block(CHB-200) |

|

|

|

|

|

|

| EXAMPLES OF TYPEIAL MEASUREMENT |

| [Curing Behaviors] |

Emulsion Polymer

|

Paints

|

Adhesives

|

UV Curing resin

|

| [Physical Properties] |

Polyester coated nylon fiber

|

Coated film for Piano

|

| Surface Curing |

Surface Physical Properties

|

Internal Physical Properties

|

|

|

| Application of RPT - 3000W |

This instrument allows measurement of viscoelastic physical properties under a curing process, as well as the surface layer

physical properties of the material. Therefore, this instrument is applicable for development/ improvement, quality evaluation,

designing and trouble-shooting production line and life evaluation of materials. |

Application of RPT - 3000W Application of RPT - 3000W |

|

| Specifications |

| Swing Angle(Maximum) |

±0.573 degrees |

| Angle Resolution |

1.749e-5 degrees |

| Swing Displacement Detection |

Inductance Non - Contact Type

Displacement Sensor |

| Period of Vibration |

0.05 ~ 2.000 sec |

| Logarithmic Damping Ratio |

0.001 ~ 6.000 sec |

| Test Temperature |

-100 ~ +400 degrees Celsius |

| Cooling System |

Liquid Nitrogen |

| Measurement Time |

1 ~ 9999 minutes |

| Option |

Ultraviolet Irradiation Device |

| Dimensions / Weight |

Main Body : 300 × 220 × 525 / 15kg

Controller : 410 × 350 × 135 / 12kg |

| Safety Device |

Safety Lamp for increasing temperature

(It turns on at 50 degrees) |

| Power Supply |

100V AC 50 / 60Hz 550VA |

|

|

| Specifications subject to change for improvement without notice. |

|

User needs to purchase the following PC and Database software for RPT-3000W.

MSAT (Multi Signal Analysis Testing)

Data processing software

The MSAT series is equipped with functions for not only testing machine operation but also data analysis, calculation and data storage for each testing mode. The operator can select curbing behaviors or physical properties depending on the purpose of the test. |

| PC operation environment OS: Windows XP Professional. Program size: 80Mb or smaller. Memory requirement: 512Mb or over. Authority requirement: Administrator authority. USB: One USB port. Display resolution: 800x600 dots or higher color display. |

|