Thiết bị tối ưu hóa quá trình hàn SolderStar WaveShuttle Selective

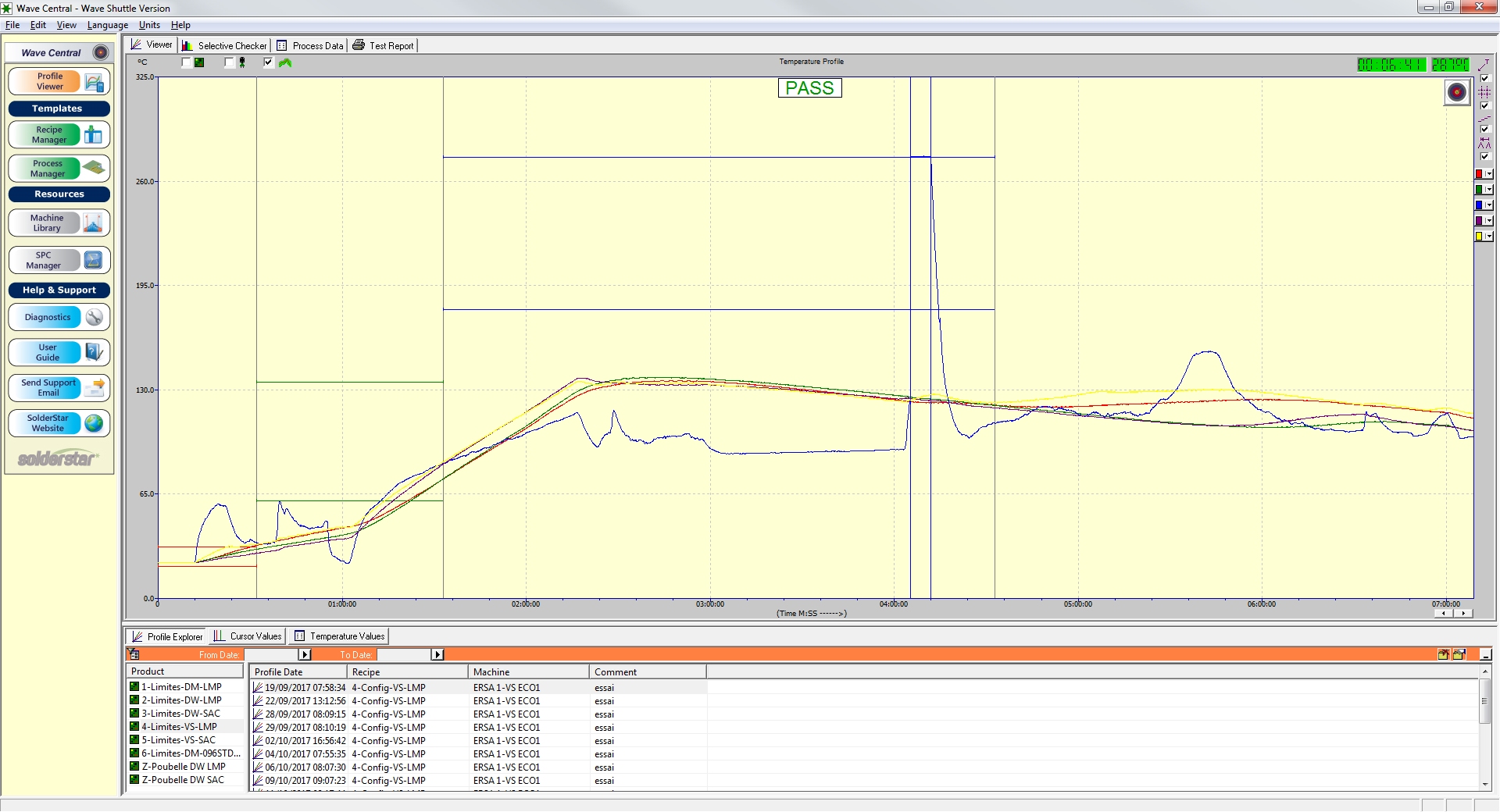

The SolderStar WaveShuttle Selective has been specifically designed for daily testing of Mini-Wave Selective soldering machines. A specially configured array of titanium wave contact sensors are arranged on the underside of this measurement fixture to allow quick and comprehensive verification of the machine functionality.

Nozzle strikes on clinched components or the PCB due to PCB warp or general tolerances can result in the positioning mechanism of the machine becoming mis-aligned. X and Y positioning mechanism and speed are verified by sweeping the selective soldering nozzles between pre-defined datum’s. An array of stepped contact sensors are employed to allow nozzle wave height measurements to be made and periodically verified.